Fatigue Performance of Additively Manufactured High Strength Steel with Cold Sprayed Coating

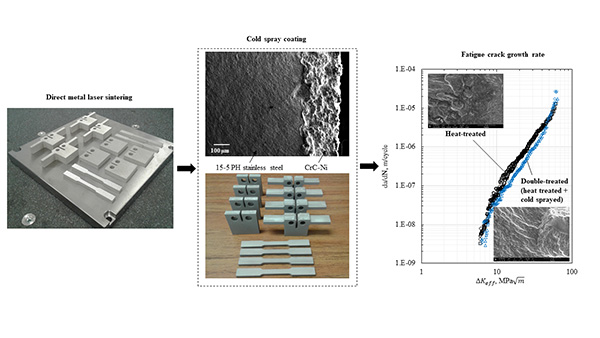

Coatings on materials play an important role in components of aerospace, unclear, energy, and defense industries as a thermal, wear, and corrosion barriers. In recent years cold gas dynamic spray, or more simply cold spray (CS), has opened a new avenue for producing protective coatings for materials, as well as near net shape part fabrication. In the CS process micron-sized particles of a metal, ceramic and/or composite are accelerated through a spray gun fitted with a De Laval rocket nozzle using a heated high-pressure helium or nitrogen such that the particles exit at supersonic velocities and consolidate upon impacting a substrate surface. CS is a relatively low-temperature coating process, as it operates under the recrystallization temperature of the substrate and feedstock powder. This lower temperature prevents phase transformation and elemental decomposition in the substrate and the deposited layer. This process also imposes some extent of grain refinement, work hardening/softening, and tensile/compressive residual stresses into the substrate, substrate/coating interface, and the deposited layer. The advent of CS and additive manufacturing of high strength metals in the recent years presents the opportunity to produce geometrically complex layered components using ultra-high strength alloys and ceramic matrix composites that can withstand the aggressive environment of gas turbines, internal combustion engines, boilers, light water reactors and fusion system components. However, the fatigue strength of a coated material in critical components which experience cyclic deformation is an overriding concern, since the mechanism of the fatigue crack growth is highly influenced by discontinuities in thermal and elastic properties of substrate and coating, as well as the state of residual stress. Research has resulted in a wide variety of ceramic matrix composites with elastic and thermal expansion properties similar to that of the substrate, which precludes spallation-failure to a great extent. However, the evolution of residual stresses in coated materials, both in the substrate and in the deposited coating following CS processing, significantly affects the fatigue performance. CS-induced residual stresses may cause a dynamic restoration of the microstructure, which significantly alters intrinsic properties of a material, introduce mechanical anisotropy and cause dimensional instability, such as distortion. Also, it has been well established that residual stresses arise in additively manufactured metal components in almost every step of manufacturing process due to the intense temperature gradients and/or mechanical forces caused by removing the support structure. Therefore, imposed residual stresses following AM processing of the substrate and the interaction of these state of stresses with the CS imposed residual stresses can significantly alter the cyclic deformation characteristic by promoting or retarding crack initiation and accelerating or decelerating crack growth. Our results reported in the "Influence of cold sprayed Cr3C2-Ni coating on fracture characteristics of additively manufactured 15Cr-5Ni stainless steel" indicated that a thin layer of high-temperature wear- and oxidation-resistant ceramic matrix composite (i.e. Cr3C2-Ni) deposited by CS coating has a beneficial influence on damage tolerance characteristics of a DMLS produced substrate (i.e. 15Cr-5Ni stainless steel). Improvement in the fracture toughness and fatigue performance of substrate material against pre-existing crack was associated with the significant contribution of CS coating on grain size refinement and improvement of nanomechanical properties at and ahead of the crack tip. This finding emphasizes the great potential of CS coating as a method for improving the fatigue life and the endurance limit of high strength alloys produced by DMLS.

Researcher: Dr. Davoud Mashhadijafarlou